GOBOTiX tests automated inspection system to identify rolling stock faults

The UK-based technology company GOBOTiX has completed a successful trial of Vehicle Underside Examination System (VUES). During the 27-month tests, this automated inspection system has detected the various types of rolling stock defects and anomalies. The solution could be a good option for the train operators to reduce their costs in rolling stock maintenance.

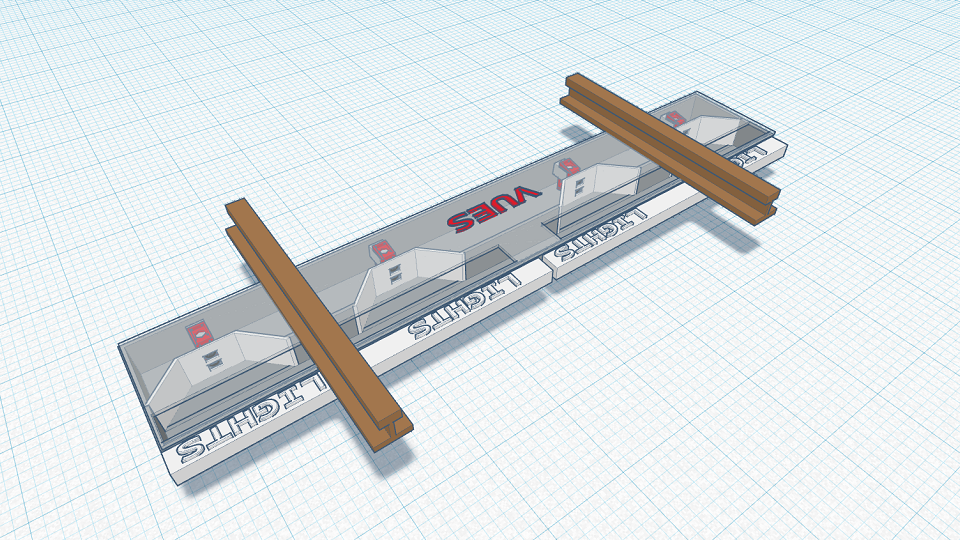

The VUES solution includes a combination of cameras, algorithms and non-visible wavelength lights. With the help of self-learning technology, it generates data and imagery, which is reported electronically to maintenance teams for investigation. The system was installed alongside the tracks on the route of Chiltern Railways, a subsidiary of Arriva UK Trains. Several times a day the GOBOTiX-developed solution was being examined the operator’s trainsets without any traffic interruption.

The tests of the VUES system have completed successfully with a lot of collected data about the rolling stock faults, including overheating components, damaged equipment, wearing gearboxes and cooling system failures. Some of them have been identified long before they were picked up during manual engineering inspections. “Continuous inspection and maintenance of rolling stock is a costly process for rail companies and even with regular checks, it can be difficult to detect faulty equipment and underlying defects. Our technology successfully detected radiator, cooling system and gearbox failures months before they led to any significant engine failures on the Chiltern Railways trains,” GOBOTiX founder Ben Davis said.

Text continues below the picture.

VUES CAD Drawing, source: GOBOTiX.

Cost savings

According to the GOBOTiX calculations, the detected failures would have saved Chiltern Railways in excess of 250,000 British Pounds a year (more than 274,000 Euros). “VUES can deliver significant cost savings for train operators, not only by providing a greater lifespan of components, better utilisation of existing stock and increased fleet service life but by reducing the level of fines that are awarded across the network for every minute a train is delayed,” Ben Davis added. The system is also capable to optimise the railway operations and increase the capacity due to fewer maintenance outages. Currently, GOBOTiX is looking for investors to take its solution from a proof of concept to a mass-market both in the UK and overseas.

GOBOTiX

GOBOTiX is a Shropshire-based technology company focused on research and development of robotics systems. It was founded by Ben Davis in 2013, following his extensive research experience at the University of Oxford, Heriot-Watt University and Edinburgh University. The company is involved in several urban innovation developments, which are rooted in the united goal of reducing costs and creating ‘Smart Cities’. For instance, GOBOTiX developed a backup safety system for recovery of self-driving cars. This solution demonstrated that failed autonomous vehicles could be safely recovered using teleoperation.